|

Ningbo Horizon Magnetic Technologies Co., Ltd.

|

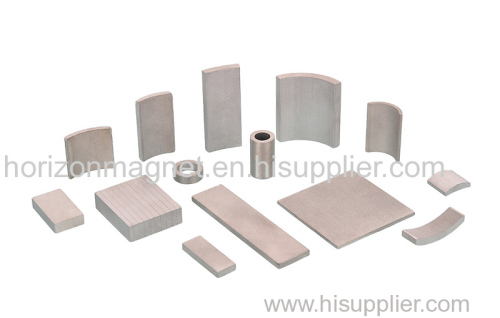

SmCo Magnet SmCo Magnet

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

SmCo Magnet

SmCo Magnet

SmCo Magnet Supplier

SmCo Magnet Factory

SmCo magnets known as Samarium, Samarium Cobalt or rare earth Cobalt magnets, are the second generation of rare earth permanent magnets. According to the difference between the production technologies, SmCo can be divided into bonded SmCo and sintered SmCo, but we are only specialized in sintered SmCo.

The sintered SmCo are anisotropic and can only be magnetized in the orientation direction. They consist mainly of Sm (Samarium) and Co (Coblat), and they are available with two series of materials, SmCo5 and Sm2Co17 often referred to as SmCo 1:5 and SmCo 2:17. SmCo5 have lower energy, Hcj (intrinsic coercive force), maximum operation temperature and Curie temperature than Sm2Co17, but SmCo5 are easier to magnetize to saturation.

They are available in a number of grades that span a wide range of properties and application requirements. They are powerful, with (BH)max range of 14MGOe~32MGOe; however, they are also very brittle and prone to cracking and chipping, so they must be handled with care and adequate protective gear. Due to their relative frailty, mechanisms and applications in which the magnets are used must be adapted and designed to support the material.

SmCo Magnet Characteristics:

High magnetic values – Br high to 11.3 kGs (1.13 T) and (BH)max high to 32 MGOe (255 kJ/m3)

High working temperature – maximum working temperature high to 250ºC~350ºC

Outstanding thermal stability – α(Br) low to -0.03 %/ºC and β(Hcj) low to -0.2%/ºC

Excellent corrosion resistance – no surface treatment needed

Excellent demagnetization resistance – maximum Hcj higher than 25 kOe (1990 kA/m)

SmCo Magnet Applications:

Due to their characteristics above, SmCo are the ideal magnetic material in following applications, particularly where the magnets are required to operate at high temperatures, across a broad temperature range, with stable magnetic field, or in a corrosive environment: travelling wave tubes, circulators, isolators, speakers, magnetron sputtering cathodes, sensors, servo motors, pump couplings, chemical pumps, magnetic assemblies, etc

Physical Properties:

Characteristics | Reversible Temperature Coefficient 20-150ºC, α(Br) | Reversible Temperature Coefficient 20-150ºC, β(Hcj) | Coefficient of Thermal Expansion | Thermal Conductivity | Specific Heat | Curie Temperature | Flexural Strength | Density | Hardness, Vickers | Electrical Resistivity |

Unit | %/ºC | %/ºC | ΔL/L per ºCx10-6 | kcal/mhrºC | cal/gºC | ºC | Mpa | g/cm3 | Hv | μΩ • cm |

SmCo5 | -0.04 | -0.2 | //6⊥12 | 9.5 | 0.072 | 750 | 150-180 | 8.3 | 450-550 | 50~60 |

Sm2Co17 | -0.03 | -0.2 | //9⊥11 | 8.5 | 0.068 | 850 | 130-150 | 8.4 | 550-650 | 80~90 |

Magnetic Properties:

Material | Grade | Residual Induction | Coercivity | Intrinsic Coercivity | Maximum Energy Product | Density | Temp. Coefficient 20-150 °C | Curie Temp. | Maximum Operating Temp. | |||||

Br | Hcb | Hcj | (BH )max | D | α(Br) | β(Hcj) | Tc | Tw | ||||||

T | kG | kA/m | kOe | kA/m | kOe | kJ/m3 | MGOe | g/cm3 | %/°C | %/°C | °C | °C | ||

SmCo5 | YX16 | 0.79-0.85 | 7.9-8.5 | 612-660 | 7.7-8.3 | >1194 | >15 | 110-135 | 14-17 | 8.3 | -0.04 | -0.20 | 750 | 250 |

YX16H | 0.79-0.85 | 7.9-8.5 | 612-660 | 7.7-8.3 | >1592 | >20 | 110-135 | 14-17 | 8.3 | -0.04 | -0.20 | 750 | 250 | |

YX18 | 0.84-0.90 | 8.4-9.0 | 644-700 | 8.1-8.8 | >1194 | >15 | 127-151 | 16-19 | 8.3 | -0.04 | -0.20 | 750 | 250 | |

YX18H | 0.84-0.90 | 8.4-9.0 | 644-700 | 8.1-8.8 | >1592 | >20 | 127-151 | 16-19 | 8.3 | -0.04 | -0.20 | 750 | 250 | |

YX20 | 0.89-0.94 | 8.9-9.4 | 676-725 | 8.5-9.1 | >1194 | >15 | 143-167 | 18-21 | 8.3 | -0.04 | -0.20 | 750 | 250 | |

YX20H | 0.89-0.94 | 8.9-9.4 | 676-725 | 8.5-9.1 | >1592 | >20 | 143-167 | 18-21 | 8.3 | -0.04 | -0.20 | 750 | 250 | |

YX22 | 0.92-0.96 | 9.2-9.6 | 710-748 | 8.9-9.4 | >1194 | >15 | 160-183 | 20-23 | 8.3 | -0.04 | -0.20 | 750 | 250 | |

YX22H | 0.92-0.96 | 9.2-9.6 | 710-748 | 8.9-9.4 | >1592 | >20 | 160-183 | 20-23 | 8.3 | -0.04 | -0.20 | 750 | 250 | |

YX24 | 0.95-1.00 | 9.5-10.0 | 730-780 | 9.2-9.8 | >1194 | >15 | 175-199 | 22-25 | 8.3 | -0.04 | -0.20 | 750 | 250 | |

YX24H | 0.95-1.00 | 9.5-10.0 | 730-780 | 9.2-9.8 | >1592 | >20 | 175-199 | 22-25 | 8.3 | -0.04 | -0.20 | 750 | 250 | |

Sm2Co17 | YXG22 | 0.93-0.97 | 9.3-9.7 | 676-740 | 8.5-9.3 | >1433 | >18 | 160-183 | 20-23 | 8.4 | -0.03 | -0.20 | 850 | 350 |

YXG22H | 0.93-0.97 | 9.3-9.7 | 676-740 | 8.5-9.3 | >1990 | >25 | 160-183 | 20-23 | 8.4 | -0.03 | -0.20 | 850 | 350 | |

YXG24 | 0.95-1.02 | 9.5-10.2 | 692-764 | 8.7-9.6 | >1433 | >18 | 175-191 | 22-24 | 8.4 | -0.03 | -0.20 | 850 | 350 | |

YXG24H | 0.95-1.02 | 9.5-10.2 | 692-764 | 8.7-9.6 | >1990 | >25 | 175-191 | 22-24 | 8.4 | -0.03 | -0.20 | 850 | 350 | |

YXG26M | 1.02-1.05 | 10.2-10.5 | 541-780 | 6.8-9.8 | 636-1433 | 8-18 | 191-207 | 24-26 | 8.4 | -0.03 | -0.20 | 850 | 300 | |

YXG26 | 1.02-1.05 | 10.2-10.5 | 748-796 | 9.4-10.0 | >1433 | >18 | 191-207 | 24-26 | 8.4 | -0.03 | -0.20 | 850 | 350 | |

YXG26H | 1.02-1.05 | 10.2-10.5 | 748-796 | 9.4-10.0 | >1990 | >25 | 191-207 | 24-26 | 8.4 | -0.03 | -0.20 | 850 | 350 | |

YXG28M | 1.03-1.08 | 10.3-10.8 | 541-796 | 6.8-10.0 | 636-1433 | 8-18 | 207-223 | 26-28 | 8.4 | -0.03 | -0.20 | 850 | 300 | |

YXG28 | 1.03-1.08 | 10.3-10.8 | 756-812 | 9.5-10.2 | >1433 | >18 | 207-223 | 26-28 | 8.4 | -0.03 | -0.20 | 850 | 350 | |

YXG28H | 1.03-1.08 | 10.3-10.8 | 756-812 | 9.5-10.2 | >1990 | >25 | 207-223 | 26-28 | 8.4 | -0.03 | -0.20 | 850 | 350 | |

YXG30M | 1.08-1.10 | 10.8-11.0 | 541-835 | 6.8-10.5 | 636-1433 | 8-18 | 223-240 | 28-30 | 8.4 | -0.03 | -0.20 | 850 | 300 | |

YXG30 | 1.08-1.10 | 10.8-11.0 | 788-835 | 9.9-10.5 | >1433 | >18 | 223-240 | 28-30 | 8.4 | -0.03 | -0.20 | 850 | 350 | |

YXG30H | 1.08-1.10 | 10.8-11.0 | 788-835 | 9.9-10.5 | >1990 | >25 | 223-240 | 28-30 | 8.4 | -0.03 | -0.20 | 850 | 350 | |

YXG32M | 1.10-1.13 | 11.0-11.3 | 541-844 | 6.8-10.6 | 636-1433 | 8-18 | 230-255 | 29-32 | 8.4 | -0.03 | -0.20 | 850 | 300 | |

YXG32 | 1.10-1.13 | 11.0-11.3 | 812-844 | 10.2-10.6 | >1433 | >18 | 230-255 | 29-32 | 8.4 | -0.03 | -0.20 | 850 | 350 | |

YXG32H | 1.10-1.13 | 11.0-11.3 | 812-844 | 10.2-10.6 | >1990 | >25 | 230-255 | 29-32 | 8.4 | -0.03 | -0.20 | 850 | 350 | |

Low Temp. Coefficient Sm2Co17 | YXG22LT | 0.94-0.98 | 9.4-9.8 | 668-716 | 8.4-9.0 | >1194 | >15 | 167-183 | 21-23 | 8.4 | -0.015 | -0.20 | 850 | 350 |

Remarks:

1. The above mentioned data of properties are given at room temperature.

2. The maximum operating temperature of magnets is shape/geometry dependent.

3. These are standard grades and others are available upon request. Where practical we will produce grades for specific applications.